Table of contents

- Typical problems of electric shutters

- mechanical problems

- electrical problems

- How to deal with problems with electric shutters

- In addition, you need depending on the damage pattern

- Roller shutter jammed

- Broken slats

- Renew slats below

- Renew slats at top

- stuck shaft

- Broken strap

- Defective belt winder

- Electrical problems - circuit breakers

- Other electrical problems

If you have electric roller shutters, you wouldn't want to be without them. It is all the more annoying when the technology goes on strike and the roller shutters no longer go up. You don't always have to call in an expert. This article explains how to fix errors yourself with a little skill.

Electric roller shutters offer comfort, but the built-in electromechanics also make them prone to failure. Here we explain in an easy-to-understand manner how to get to the bottom of the cause of the error and how to carry out the repair.

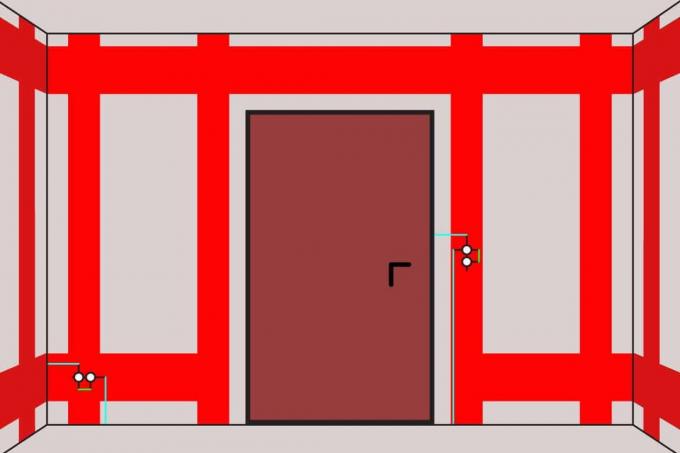

Typical problems of electric shutters

In the course of their life, electric roller shutters develop defects that can have different causes. The problems naturally become more common with age. In order to be able to narrow down the troubleshooting, it is helpful to know the common, typical problems with electric roller shutters.

mechanical problems

- the roller shutter is stuck in the guide rails

- the shaft is blocked in the roller shutter box

- the belt is torn (only for systems with a belt)

- the belt is not rolled up correctly (only for systems with belt winders)

electrical problems

- Residual current circuit breaker in the fuse box has tripped

- Defective drive motor (depending on the type, this is located on the belt winder or directly on the shaft in the roller shutter box)

- Defective or incorrectly adjusted limit switches

- Control unit is defective

A notice:

In rare individual cases, there are other causes for problems with electric roller shutters. The above list does not claim to be complete.

How to deal with problems with electric shutters

All the work described below differs depending on the model. In any case, the manufacturer's relevant installation and maintenance instructions should be followed.

Safety note: If the roller shutters can only be reached by ladder from the outside, it is essential that you have a second person secure them. In addition, a fall protection system adapted to the corresponding working height should be used.

It makes sense to first deal with the possible mechanical causes.

The following tools and parts are required for the relevant work:

- if necessary, ladder and fall protection

- Screwdriver (depending on the roller shutter model, slotted, Phillips or Torx screwdriver in the appropriate sizes)

- a small hammer

- a sharp pair of scissors

In addition, you need depending on the damage pattern

- new slats or

- two new shaft bearings or

- a spare belt or

- a new spring for the belt winder

Roller shutter jammed

You can easily determine whether the roller shutter is stuck in the guide by trying to push it up manually. A closer look is often enough to see whether the slats are crooked in places. This is a clear indication of a tilted roller shutter, which is therefore blocked. In this case, it may be sufficient to carefully "adjust" the roller shutter so that it runs in the lateral guides without tilting.

Carefully dosed blows with a small hammer, without damaging the lamellae, can also solve the jamming. It is also possible that one of the side guide rails has come loose in places and is responsible for the roller shutter jamming. In this case, return the rail to its original position and reattach it.

Broken slats

Individual slats can also be broken and jammed. In this case, however, the entire roller shutter does not have to be replaced at once. It is possible to exchange individual slats. The procedure depends on the area in which the damaged fins are located.

Renew slats below

- Dismantle the end strip in order to be able to pull out the slats downwards.

- Carefully slide the roller shutter out of the lower ends of the guide rails until the damaged slats can be removed.

- If necessary, secure the strap (if equipped) to prevent further slats from falling out until the new slats are ready for installation.

- Insert and install the new fins as well as the undamaged removed fins.

- Install the end strip to secure the roller shutter and unlock the belt if necessary.

Tip:

It usually makes sense to have a second person help you when replacing the slats. Especially when it comes to large roller shutters, it is easier for two people to remove the old slats and insert the new slats without jamming.

Renew slats at top

- Open the shutter box cover.

- The first accessible slat must be removed.

- Remove the remaining fins until the damaged fins are also removed.

- Insert the new slats as well as the undamaged slats that were removed.

- Reinstall the roller shutter box cover.

Tip:

Secure the belt (if available) to prevent the roller shutter from falling down while working, depending on the position.

stuck shaft

To check for a possible stuck shaft as the cause of the problem, open the shutter box cover. By manually turning the shaft, it can be determined whether it is movable or stuck. If the shaft is sticking, the shaft bearings are probably seized and need to be replaced. This work differs depending on the roller shutter model. Clarify with a specialist company whether the bearings in your roller shutter should be replaced by a layperson.

Broken strap

If the roller shutter cannot be raised due to a torn belt, it must be replaced. To do this, the roller shutter must be manually pushed up and secured. Then open the belt winder and the roller shutter box cover. Remove the torn belt and insert the new one in reverse order. This must be shortened to the right length and inserted into the belt winder and attached to the roll. Pull the strap up into the roller shutter box to attach it to the roller of the shaft. While the roller shutter is now slowly and carefully lowered, the belt winds onto the upper roller.

Defective belt winder

If the reason for the malfunction of the roller shutter lies in the belt winder, then it is worth checking the tension spring of the belt guide. This can lose tension or break over time. In these cases, replace the spring with a new one. If this measure is not possible or does not lead to the desired success, you can replace the entire belt winder with a new one.

Electrical problems - circuit breakers

If all mechanical causes that prevent the electric roller shutter from moving up have been ruled out, then there is an electrical problem. If a tripped residual current circuit breaker is responsible, you can reset it so that the roller shutter works. If the switch trips again, the cause should be investigated.

Other electrical problems

If there are problems with the electrical system, it is not advisable to carry out a repair yourself for safety reasons. Always contact a specialist company for electrical work.

Home editorial office

Home editorial office

Learn more about power/electrics

Balcony power plant 800, 1000, 1200 watts: what is allowed?

In times of energy crisis and energy transition, solar panels on the balcony offer an easy way to generate and use sustainable electricity. We explain what is behind the so-called balcony power plants and how many watts are allowed during operation.

Fault location: how do I find the defect in the cable?

If a cable in the house or apartment is defective, you usually only notice it because some electrical devices are no longer working. Then you should start looking for the error. Exactly how this fault location works is explained here.

16 ampere fuse: how many sockets / watts possible?

A 16 amp fuse is used in most households. But how many sockets or consumers and how many watts are permitted with them? We show how the maximum load can be calculated and what else needs to be taken into account.

Drilling holes for sockets: dimensions and distances

With the right tool, drilling holes for sockets is no problem. Important: distances should be maintained to the nearest millimeter if possible. Precise work is therefore of particular importance when making a hole for the socket. You'll find more about it here.

Lay TV cable and satellite cable | 5 tips for good reception

In order to lay TV and satellite cables, some prior knowledge of the subject is required. In addition, the user should rely on good quality for the cables. Otherwise, the devices to be connected cannot work properly and poor picture quality will result.

Lay and connect underground cable | Laying depth & costs

If underground cables are to be laid and connected, attention must be paid to the correct procedure. Both the laying depth and the connection and connections must be coordinated. Here you can find out how to proceed and the costs to be expected.