Table of contents

- Wood

- bamboo

- Bangkirai

- Cumaru

- douglas fir

- Oak

- Jaw

- larch

- Black Locust

- Plastic for decking

- Decking board made of WPC

If the terrace floorboards are to be replaced or newly laid, the question of the desired material is the top priority. In the meantime, a large selection of different types of wood, but also plastic and WPC is available on the market. But what are the differences between the materials and what are the respective advantages and disadvantages.

Wood

The decking made from the raw material is a classic and looks particularly natural. Other advantages of this material are that it is durable and available in many different variations and is also easy to process. The following types of wood are mainly used for terraces:

- Bamboo (Bambusoideae)

- Bangkirai (Shorea laevis)—Yellow Balau

- Cumaru (Dipteryx odorata) – Tonka bean tree

- Douglas fir (Pseudotsuga menziesii)

- Oak (Quercus)

- pine (pinus)

- Larch (Larix)

- Black Locust (Robinia pseudoacacia)

The differences between these types of wood are not only in the look, but also in the respective properties of the material. In general, however, the renewable building material has the following advantages:

- natural grain and therefore visually appealing

- Long lasting and durable with proper care

- high breaking strength

- Protection of the material possible by simple measures

- can be edited well

- optical diversity

However, the natural material not only has advantages, but also disadvantages. These are:

- optical change due to UV radiation and weather

- Formation of splinters, for example due to the influence of force

- Preservation measures necessary

Which properties the natural material also has depends of course on the respective species.

bamboo

Strictly speaking, bamboo as a material is not wood, but comes from a grass. It is quite light in coloration, but this can vary widely depending on the exact species. The material can come from slow or fast-growing bamboo species, which in turn affects the hardness. Slow-growing species produce harder lumber. In general, the planks made of the material are comparatively soft and can therefore be damaged more quickly.

In addition, the raw material does not contain any permanent, repellent substances. As a result, it must be regularly protected against fungi and insects with suitable means.

Bangkirai

The type of wood with the exotic-sounding name belongs to the hardwoods and is often used for floors because it is extremely resilient. The grain is very fine and homogeneous, optically rather inconspicuous. A clear advantage is that this type of wood is naturally highly resistant to fungi and insects and therefore does not require any special protection. However, it tends to crack and should not come into direct contact with ferrous metals, otherwise it will turn a strong grey-blue colour.

In addition, special drills are required for processing the heavy, hard wood; simple wood drills are not sufficient.

Cumaru

Cumaru or Cumarú is a tree from South America that, like Bangkirai, is extremely hard and resilient. It is only commercially available in small quantities, but is very stable and durable. Due to the substances it contains, it is resistant to fungi and insects even when untreated, which makes care much easier. However, the processing is difficult due to the great hardness. Special tools and pre-drilling holes are required for installation. Another well-known name is also tonka bean tree (bot. Dipteryx odorata).

douglas fir

Douglas fir is a popular outdoor material, especially in America. It has a medium hardness and can therefore be processed relatively well, is comparatively durable and also withstands the effects of the weather. It also has a decorative grain and gives off a pleasant, albeit pungent, woody smell.

However, it is advisable to apply appropriate protection.

Oak

The term oak includes several different types of oak, such as white oak and red oak. The advantages and disadvantages of the wood as well as its appearance vary accordingly. In general, however, the natural material is easy to process and treat with protective agents. When attaching the decking, however, care must be taken that the material can quickly break and tear due to its nature. It is therefore advisable to make pilot holes.

In addition, suitable protective agents should be used, as there are also considerable differences in oak wood when it comes to resistance to harmful influences such as weather, fungi and insects.

Jaw

Pine wood has a medium to hard strength and is easy to process, so it is used in a variety of ways and with pleasure. Protection with paint or glazes is advisable in order to extend the service life and at the same time to protect to obtain a light to medium color or to prevent discoloration and staining.

Since pine wood is readily available, the material is also a cheap choice in terms of price. When making your selection, however, you should pay attention to the type of pine tree you are dealing with. Because with the American pines there is a distinction between soft and hard types. If possible, a hard variant should be chosen for the terrace floorboards, as these are more resilient and durable.

larch

Larch wood is one of the harder softwoods, but overall it is only moderately hard and resilient. However, this is usually completely sufficient for terrace boards. The material is easy to process, although pre-drilling is recommended to prevent cracks.

The material should also be protected to prevent insect or fungal infestation and to extend its service life. In addition, the attractive grain of the wood can be emphasized with suitable means.

Black Locust

Robinia is one of the hard and resilient, durable woods. The material has a striking grain, is comparatively easy to work with and is also resistant to moisture. However, protection against the harmful effects of paint or glaze makes sense in order to increase the service life again.

Due to the hardness, it is again recommended to make pilot holes when installing the decking.

Plastic for decking

Decking boards made of plastic or solid plastic are not usually offered, as the material quickly becomes brittle and rough due to the effects of the weather. In addition, it often does not have the required breaking strength.

A notice:

When talking about plastic floorboards, WPC decking boards are usually meant.

Decking board made of WPC

WPC is a so-called composite material consisting of wood and plastic. It therefore represents a combination of the materials already mentioned and their properties. The main advantages of this composite material are that it is very easy to care for and moisture-resistant. In contrast to types of wood, it does not require any special or repeated sealing, such as varnish or glaze.

In addition, the material can be shaped much more freely than wood and is also splinter-free. Compared to plastic, the material is more rigid and expands less due to temperature fluctuations. The disadvantages, however, are that the composite material absorbs more moisture than solid plastic due to the wood content and is also less break-resistant than wood. A typical grain is also usually missing, so that there can be optical deductions.

Home editorial office

Home editorial office

Learn more about building a terrace

Effectively remove lichen from paving stones

A covering of lichen on paving stones not only looks ugly, but also poses the risk of slipping. With the following tips, you can easily and effectively remove unloved roommates from your patio and garden paths.

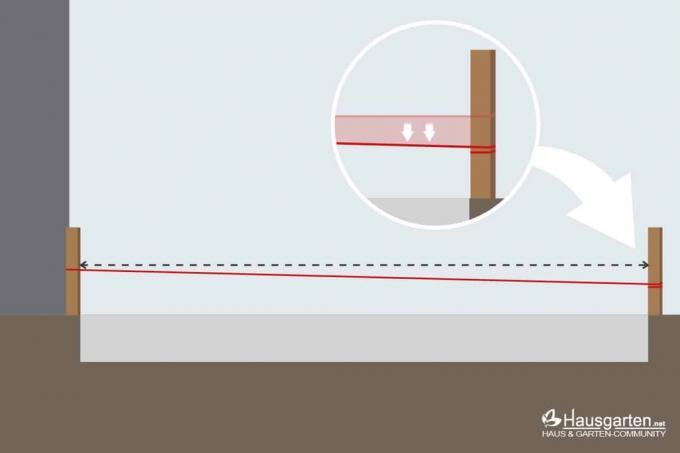

Distance between decking boards | Information on terrace construction

A correct distance between the terrace boards and the substructure determines the longevity of a terrace. Only well-ventilated wood dries out optimally to prevent the formation of mold and rot. Last but not least, the movement tolerance plays another decisive role.

Lichen: remove white spots on paving stones

In addition to mosses, yellow-white coverings often adorn the paving stones of our driveways. It is not uncommon for dull stains to spoil the joy of the new stones shortly after they have been laid. Although sometimes wrongly dismissed as an indication of poor material quality, this is actually a natural phenomenon.

Determine the gradient on a terrace: this is how it works

Rain, snow or ice, depending on the weather, water collects on the patio floor. The terrace needs a slope so that no annoying puddles form on it. Calculating the slope is easy once you know the length and material of the decking.

Terrace construction: the 1×1 of the substructure

When constructing a terrace, the substructure plays a decisive role in determining the service life. However, it must also be tailored to the respective material and the substrate. Here you can find out what to look out for.

Laying a wooden terrace on exposed concrete slabs: this is how it works

A wooden deck is warm and natural, welcoming and cosy. But what if you already have a terrace made of exposed aggregate concrete? This is not a problem but an advantage. Because this can be used directly as a basis. We show how.