Table of contents

- Why grey?

- How do you change the concrete color?

- The preliminary considerations

- 1. The starting color

- 2. aggregates

- 3. The amount of pigments

- 4. efflorescence

- The processing

- Common pigments

- Professional pigments

- basalt

- copper oxide

- iron oxide

- DANGER

- Special case oil shale cement

- Coloring with additives – the alternative

- Pigmented glazes

Concrete is seen as grey, solid and simply unattractive. But it does not have to be like this. While modern technology allows for ever more organic and slender concrete shapes, you can go a different way with your private projects: How about an alternative to the dreary Gray? We explain which methods and work steps you use to specifically color concrete.

Why grey?

Why should you even think about coloring your concrete yourself? Can't the manufacturers do this directly? It doesn't always have to be grey. Well, it doesn't always have to be grey, but unless you make an extra effort, concrete is and will inevitably be this shade. The reason is the most important ingredient in concrete: the cement. In addition to a few other additives, it is primarily made from limestone and clay, which occurs naturally in the form of a mixture, usually as so-called "marl". The raw materials are burned at almost 1,500 degrees Celsius above the so-called sintering limit and then ground into the well-known powder. Both the raw materials themselves and the firing process lead to the well-known, unappealing color.

How do you change the concrete color?

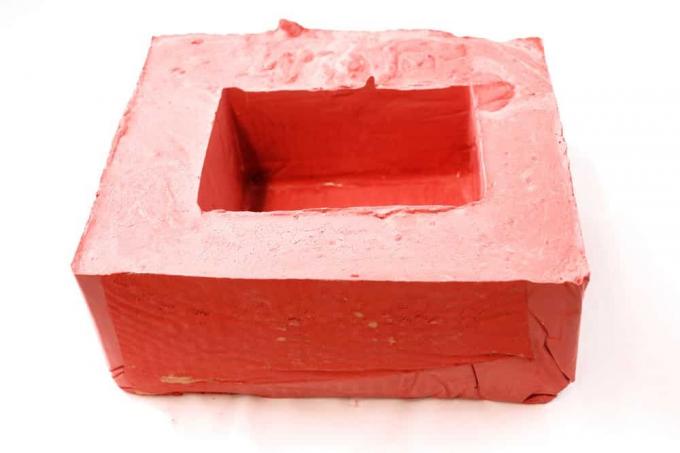

Various manufacturers have also recognized that additional colors increase diversity and make concrete interesting for people who want to avoid the uniform grey. For large amounts of concrete, such as when building a house, you should leave the coloring to the professionals. But if you need small amounts of concrete for garden walls, planters or handicrafts, you can create the desired color yourself using the means described below. Irrespective of the chosen method, different substances are buried in the concrete, thus achieving through-colouring. Unlike paint or coating, the color is present throughout the material and will remain even if the surface is scuffed or damaged.

The preliminary considerations

Before coloring, there are a few things to be aware of:

1. The starting color

Because cement is naturally gray, bright, bright colors are very difficult to achieve. If you want light colors, you should use so-called white cement for your concrete. This is naturally not pure white, but it is significantly lighter than the well-known grey. The reason for this is the very low proportion of darkening iron oxides.

2. aggregates

Sand or gravel are often used as aggregates in concrete. Of course, these cannot be colored through and are recognizable in the later concrete as non-colored particles. While sand as a whole only appears as a brightener of the colour, with gravel every single pebble is the made it to the concrete surface, at the latest over time due to the thin layer of cement flaking off readable. This effect can be used in a targeted manner, but can unintentionally impair the result if it is not taken into account.

3. The amount of pigments

4. efflorescence

All concrete will, over time, sequester a certain amount of salts and other chemical compounds on its surface. One speaks here of the so-called efflorescence. This usually light to white layer causes the natural gray and added colors to appear lighter. The efflorescence can be removed with water pressure or sanding, but it can reappear. As a result, for example, concrete that is initially deep black will in most cases give way to anthracite or even a very dark black-grey over the long term.

The processing

The pigments added to the concrete are always processed in the same way, regardless of the type of pigment:

- Required volume of concrete determine

- Determine the amount of cement for the concrete volume according to the manufacturer's instructions, taking into account aggregates (sand, gravel).

- Weigh the pigment according to the manufacturer's instructions in relation to the amount of cement

- If available, use the manufacturer's color scale to determine the proportion of pigment to cement

- Thoroughly mix pigment and dry cement to avoid later color clusters

- Create and process concrete in the usual form from a pigment-cement mixture, water and aggregates

DANGER:

Wearing safety goggles and a dust mask is recommended not only for the very fine pigment, but also for handling the harmful cement. The finest particles can enter the airways or eyes and cause permanent damage.

Common pigments

There are different pigments that can be used to color concrete. Here you will find the most common and practical ones.

Professional pigments

Various manufacturers now offer specific pigments for coloring concrete. The color palette is constantly increasing and today already includes all common main colors. The gradation of hue, on the other hand, is controlled by the amount of pigment added.

basalt

The pigment of the same name, ground from basalt rock, is available from artists' supplies. Although stone powder in its pure form is mostly gray to olive green in appearance, it leads to a strong black coloring in the concrete. Depending on the dosage, colors ranging from anthracite to various shades of gray can also be achieved.

copper oxide

Copper oxide, also known from horticulture as a weed killer, can also be used as a pigment. Depending on its chemical composition, it usually achieves green, more rarely green-brown colorations.

iron oxide

Just as iron colors human blood red, in the form of iron oxide it is able to color concrete in shades of ocher to brown-red. It is available in art supply stores, as well as in numerous handicraft or chemical supply stores.

DANGER

Again and again one reads about coloring concrete dark to black by adding soot or charcoal powder. Although this also achieves a darkening, these substances are organic compounds, so that neither the durability nor the effect to be achieved are guaranteed. The durability of the concrete itself can also be affected by the admixture of organic substances to its mineral base substances. At this point, we strongly advise against using charcoal or soot to color concrete!

Special case oil shale cement

If you want a red-brown color, you can use a special cement, the so-called oil shale cement, instead of additional pigments. Instead of normal marl, this is made from oil shale, ultimately a special form of the composition of clay and limestone. It produces a reddish-brown hue by itself, but is more expensive than regular cement in terms of cost. Here it is important to weigh up the cheaper option before buying - oil shale cement or normal cement with pigments.

Coloring with additives – the alternative

Instead of coloring the cement and therefore the core element of the concrete, there is another way to influence the color. Today there is a large number of different types of gravel and crushed stone, which differ greatly in their colour. The technical suitability of these types of gravel is hardly relevant, especially for less heavily stressed concrete, such as in horticulture. Instead, a clear contrast to the gray of the concrete can be achieved by choosing a strong, intense color. How about, for example, deep black or pure white gravel in the gray of the cement? While the colors are easy to tell apart up close, the human eye mixes them together from a distance and arrives at a uniform mixed tone of both colors.

Pigmented glazes

Finally, the possibility of coloring existing concrete components with glazes containing pigments should be briefly addressed here. The manufacturers of these agents claim that the pigments penetrate a little deeper into the material due to the suction effect of the concrete pores and thus actually color the concrete. However, since the depth of penetration is very limited, it is – as long-term observations show – ultimately more of a problem very durable surface coating, which in the real sense does not belong to the possibilities of concrete coloring.

Home editorial office

Home editorial office

Learn more about concrete, screed and cement

Fresh screed: when can it be walked on?

Screed is the basis for many floor coverings. It is durable and easy to care for. However, if the load is applied too quickly after application, it can be damaged, with costly consequences. We show how long the drying time is.

What is fiber concrete? | Features & Best Practices

What is fiber concrete? This term describes special concretes that are mixed with different fibers. They expand the possible uses in many ways and have an effective effect on the stability and durability of the concrete.

What is trass cement? | The differences to cement

Trass cement describes a special type of cement with corresponding amounts of trass. The additive makes the mortar mixed from it more resistant and is effectively suitable for certain areas of application. In this guide you will find out how the mixture differs from conventional cement mixtures.

What is flow concrete | Properties & Applications

As the name suggests, flowable concrete is a much more fluid mass than conventional concrete. This is made possible by adding a flow agent. You can find out about the properties and areas of application of concrete in this guide.

How much does a cubic meter of concrete cost? | precast concrete prices

The independent production of concrete is done in a few simple steps thanks to ready-mixes from the hardware store. The so-called ready-mixed concrete consists of various components and is available in different variants depending on the intended use. The price per cubic meter depends on several factors.

Disposing of concrete: what to do with broken concrete?

Broken concrete often occurs during conversion or demolition work. It is clear that the chunks do not belong in the normal household waste. However, this raises the question of whether concrete is building rubble, construction waste or even hazardous waste.