Table of contents

- Inflow problems: 3 causes

- Small amount of water

- Inlet strainer clogged

- Check induction chamber

- Process disruptions: 4 causes

- Clogged lint filter

- Clogged drain hose

- Defective drain pump

- V-belt problems

If your washing machine has problems with the drainage or inlet, it can no longer be washed efficiently. Fortunately, there are effective and quick solutions to the individual problems.

Inflow problems: 3 causes

The most common cause of inflow problems is a turned off water supply. Therefore, first check whether the tap on your washing machine is turned on so that water can be fed into the device at all. Only then should you use one of the solutions below.

Small amount of water

If there is not enough water available, the individual programs cannot be carried out effectively. The result is soiled laundry that has hardly been cleaned. This is caused by a clogged or damaged shut-off valve. You can determine this problem with the so-called bucket test:

- Disconnect the washing machine from the electricity

- Dismantle the inlet hose including the Aquastop

- Hold the bucket under the faucet

- Use 5 l or 10 l bucket

- Turn on the faucet fully

- measure time

Ideally, up to 20 liters per minute run through the inlet tap. Use the bucket test to determine the exact time. A 5 liter bucket should be completely full after 15 seconds, a 10 liter bucket after 30 seconds. If this is the case, the small amount of water is not caused by the inlet tap. If this time is not reached, there are problems with the shut-off valve. Contact a professional to have the valve checked.

A notice:

After opening the faucet, turn it back half a turn if it is an old model. With this step you prevent the inlet tap from getting stuck, which in turn could limit the function.

Inlet strainer clogged

The inlet strainer sits at the end of the water-carrying hose and prevents deposits or foreign objects from entering the machine. This can clog it. To check the strainer, disassemble the inlet hose from the machine. Locate the screen and use pliers to gently pull it out of the machine. Check it for possible deposits or dirt. It is then cleaned like an aerator (aerator on the tap):

- rinse under running water

- Soak in vinegar if there are limescale deposits

- Flush hose

- Mount hose and strainer

Check induction chamber

The dispenser drawer could also be the cause of the problem. This is the chamber that houses the detergent drawer. Pull out the detergent drawer and check the chamber for debris and dirt. Remove detergent residue with a brush and water, while limescale is treated with vinegar or citric acid. After cleaning, put the detergent drawer back in place and start a short program without detergent or laundry. Pull the drawer out a crack and check the water flow. If the water is trickling or slow, one of the following components is damaged:

- magnetic valve

- aquastop

You can replace the Aquastop yourself by purchasing a new hose with the component. If that still didn't help, have an expert check the solenoid valve.

Tip:

If, on the other hand, water gets into the machine without any problems, but it indicates a problem with the inlet, the air trap is probably clogged or the pressure cell is defective. If this is the case, you should consult a professional as these problems cannot be solved without the necessary know-how.

Process disruptions: 4 causes

If there are drainage problems, the water can no longer be drained from the drum. It stays in the machine even after spinning. The result is soaking wet laundry that is even too heavy to hang.

Tip:

If you are unlucky, the washing machine will no longer drain the water due to defective electronics. Be sure to contact a professional with this problem.

Clogged lint filter

The fluff filter should be emptied and cleaned at regular intervals to guarantee trouble-free operation. As soon as the water does not drain, the first thing you should do is check the lint filter. Follow these points to get it working again:

- Locate the lint filter flap

- is located in the front of the machine

- can be pried open with a screwdriver

- Place shallow pan or bowl under machine

- Unscrew the fluff filter

- Water will flow out of the sieve

- Pull out the sieve completely

- Remove foreign objects, hair and lint

- Clean the sieve under running water

- use high water pressure and brush

- Also check the opening of the sieve

- clean if necessary

- Let the fluff filter dry

- reinstate

- close the flap

- carry out a test run

Clogged drain hose

As with the inlet hose, it can happen that the outlet hose is clogged. Disassemble the hose and rinse well. Fluff, hair and foreign objects often collect in the hose and prevent the water from draining.

Defective drain pump

It becomes problematic when the drain pump in the device is defective. This is not recognizable from the outside, but you can listen for a rattling or cracking sound when the water is sucked out. If this is the case, the drain pump is definitely damaged. However, the generation of noise is not always the case. If cleaning the drain hose and lint filter does not help, have a professional check the pump and repair or replace it as necessary.

V-belt problems

Sometimes the process can be disrupted by a slipped or torn V-belt. The V-belt ensures that the drum is set in motion. Without the V-belt, the drum can no longer be moved, which makes it difficult for the water to drain off. If the solutions mentioned so far have not helped, contact a specialist company to have the V-belt checked and replaced if necessary.

Home editorial office

Home editorial office

Learn more about power tools

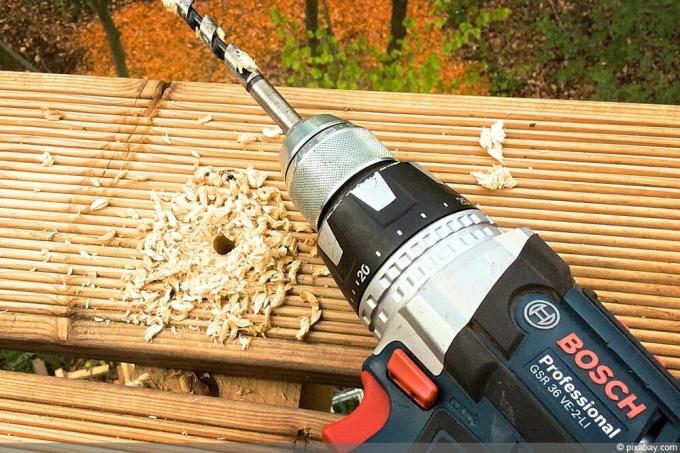

Drill vs impact drill: 5 differences

If you have to drill or screw, you need the right tool, especially with hard and difficult materials. But what is better? Drill or impact drill and what exactly are the differences between the two variants?

Hammer drill vs impact drill: 6 differences

Hammer drill or impact drill? This question arises before every purchase. But what are the differences between the types of devices and for which purpose are they each suitable? We provide answers to these questions and tips on how to choose.

Bosch cordless screwdriver: blue or green? | All differences explained

When choosing a Bosch cordless screwdriver, many people ask themselves: should it be a blue or green model? We've explained all the differences to make it easier to decide between devices.

Build a foil tunnel yourself – DIY instructions for a simple plant tunnel

If there is a polytunnel in the garden, you can outsmart bad weather. Well protected from rain, hail and frost, vegetables and salads thrive. You don't have to dig deep into your pocket for this practical garden helper. This DIY guide explains how to build a simple plant tunnel yourself.

Garden marshmallow / hibiscus not blooming - causes + special care

If the garden marshmallow - better known as hibiscus - does not bloom, there can be various reasons. With a little research into the cause and special care, the problem can usually be solved. Here we reveal what is important.

Refining OSB panels: painting, varnishing or wallpapering?

OSB panels are versatile building materials that, depending on the type, can be used for both general and load-bearing purposes in drywall and wet areas. But how can they be refined and what do you have to pay attention to? We'll tell you.