Table of contents

- Note the height of the wooden ceilings

- Check the durability of the substructure

- Check the condition of the wooden panels

- Formation of condensation under the wooden panels

- Wood as a natural raw material

- Check the attachment of the ceiling panels

- Calculate the need for work materials

- Prepare the tools for the fairing

- Cutting the sheetrock

- Screwing the plasterboard to the wooden ceiling

- Joint edges

- Cover the corners of the room with end moldings

- Design of the new ceiling

Old wooden ceilings have their charm, but they often appear a bit conservative or they require a complex refurbishment. As an alternative to demolition, you can design wooden ceilings with plasterboard. You get a smooth ceiling that you can paint or cover with wallpaper. The effort is small and the costs are moderate, so you should include this alternative to demolition in your considerations.

Note the height of the wooden ceilings

If you plan to cover the wooden ceilings with sheetrock, you should take into account in advance that the height of the ceilings will be reduced as a result. This is particularly serious if there is insulation under the wooden ceiling, which is quite common in older houses. If the room is already very low due to the wooden paneling being attached to the ceiling, you should take into account that the height will be reduced by another centimeter. This plays a subordinate role in the habitability of the room. However, if you have installed cabinets that reach the ceiling, it may be that this furniture after the cladding no longer fit in the room and can be shortened or placed in another room must.

Check the durability of the substructure

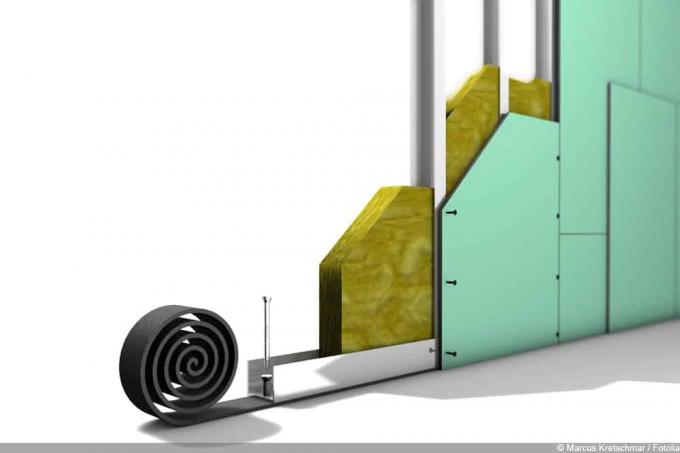

Although plasterboard has a low weight, it still weighs a total of 7.5 kg to 10 kg per square meter. Before deciding to use sheetrock for the ceiling, you should check whether the substructure can hold this weight. It must be avoided under all circumstances that the construction falls from the ceiling again because it does not get sufficient support.

Check the condition of the wooden panels

It is very important that you check the condition of the wooden panels. Before you invest in sheetrock, it is very important that you take a good look at the nature of the wood. It is advisable that if in doubt you seek the advice of a professional. If the wood is moldy or has become porous due to woodworm infestation, there is little point in cladding, as it could become unstable. Only when the wood is in optimal condition and has a high ability to support the weight should you decide on a cladding.

Formation of condensation under the wooden panels

If you ask a professional for advice, they will often recommend that you remove the wooden ceiling. The background is that the wall structure changes when the plasterboard is attached. Condensation can form. This condensation attacks the wood, but also the walls. After a few years, you notice unsightly stains and have to remove the entire construction. Before cladding the ceiling, examine the walls for damp spots and, if necessary, look for the cause. If the ceiling or the adjoining wall has damp spots, you must dry them before applying any panelling.

Wood as a natural raw material

Wood is a natural raw material that works. As a result, cracks may appear in the sheetrock construction over time. If you have covered the ceiling with wallpaper, these cracks can become visible. There is not much you can do about the changes in the wood. If the ceiling is very dry and porous, it helps to apply an oil or paint before covering to close the pores a little. This will help prevent cracks from forming in your new ceiling.

Check the attachment of the ceiling panels

Checking the stability of the wooden ceiling is very important. The wood can be screwed to the ceiling, which is very stable. Here you can make the disguise without hesitation. However, if the wood is only attached to the ceiling with small clamps and not screwed, it is advisable to fix the wood with screws before you fix the sheetrock.

Calculate the need for work materials

Before you can start with the actual cladding of the wooden ceilings, it is important that you determine the need for working materials. To do this, measure the length and width of the wooden ceiling and calculate the area in square meters that you want to cover. Sheetrock is available in a variety of sizes. In this way, you can adapt the requirements very well to your project and do not have too much waste.

For the cladding, you will still need screws that should be long enough to hold the plasterboard securely to the ceiling. Dowels are not necessary because Rigips is a soft material into which you can screw the screws directly.

Prepare the tools for the fairing

It is an advantage if you have the tool ready before you start your work. This saves you time because you have everything you need right at your fingertips. You will need the following tools to work on the ceiling:

For cutting the plasterboard:

- Cutter knife or small circular saw

- large table or trestle table

- Tape measure, ruler and pencil

For attaching the sheetrock to the ceiling:

- safe ladder

- screwdriver or

- cordless screwdriver

It is recommended if you use a powerful cordless screwdriver. Depending on the size of the ceiling, you will work with your hands raised for several hours. Manually screwing the panels together can be very tiring.

Cutting the sheetrock

In most cases it will be necessary to cut the sheetrock to size. It is an advantage if you carry out this step before you start with the actual fastening. If possible, do the cutting outdoors, in a garage or workshop. When cutting, a light-colored dust forms that settles on the furniture if you make the cut directly in the room where you want to design the ceiling. Screwing the panels to the ceiling wood leaves no residue, so you don't necessarily have to remove the furniture from the room.

The cut:

- Calculate the required length and width of each panel based on the size of the ceiling

- Draw a mark on the cut edge

- Make the cut

It is an advantage if you mark the later position of the individual panels. You can use numbers for this. This is especially true when the ceiling isn't quite straight, which is common in older homes. Then for the cladding you will need plates with a special cut. You can find them more easily if they are marked with a number.

Screwing the plasterboard to the wooden ceiling

Start at one corner of the room and work your way to the other corner of the room piece by piece with the cut panels. It is recommended that you set a screw about every ten centimeters to ensure that the construction is held securely. Make sure you lay the sheetrock edge to edge. There shouldn't be an unsightly gap between two plates.

Joint edges

After attaching the panels you can see that visible butt edges have formed. This is unavoidable due to the slightly curved shape of the sheetrock. Seal these butt edges with plaster. This results in a uniform smooth ceiling construction.

Cover the corners of the room with end moldings

At the corners of the room, unsightly joints can result from the cutting of the sheetrock. If you want a uniform construction, opt for the attachment of end strips. These are attached to the ceiling with small nails and are available in many different designs. This gives you a uniform ceiling construction that also looks very appealing.

Design of the new ceiling

Once you have completed the work on the ceiling, you will get a uniform and smooth white surface that you can now design according to your preferences. Rigips can be very well covered with wallpaper. They use classic wallpaper paste, which connects perfectly with the surface of the sheetrock. Wallpapering is so easy.

Alternatively, you can also paint your new ceiling. However, if you choose this option, it is important that you have perfectly closed the joints. Imperfections would be clearly visible under the paint while disappearing under the wallpaper. The combination of woodchip wallpaper and a coat of paint is of course also possible.

Home editorial office

Home editorial office

Learn more about drywall

Plastering plasterboard: with fabric tape or without?

Filling plasterboard is time-consuming, but can also be done without much manual skill. However, the question arises as to whether a fabric tape should be used or whether this can be dispensed with. We give the answer.

Rigips substructure: spacing of the battens

Rigips panels are useful for cladding walls and ceilings. Screwing it to the substructure is also easy. But the distance between the battens and counter battens that needs to be kept raises questions again and again. Here are answers.

Where can you dispose of plasterboard cheaply?

Sheetrock panels are used during construction or renovation work and it is not uncommon for some of them to be left over that have to be disposed of. Since this is classic construction waste, disposal is associated with costs. However, cheaper disposal alternatives are readily available.

build a stud wall | Cost & Instructions for Lightweight Wall

Building a stud wall - to create a confined space - can be practical, but it is always easy and relatively inexpensive. But how does the structure work and what costs must be expected? Our guide will tell you.

Laying Fermacell panels | 10 and more processing and trimming tips

Laying Fermacell panels is also possible for laypeople without any problems if they pay attention to a few special features and the right procedure. With our tips for processing, cutting and laying, it's really easy.

Creating a shadow gap on the ceiling | Drywall & wooden ceiling

A shadow gap is always necessary for ceiling cladding, but it also comes with a number of advantages and options. A precise and coordinated procedure is important when preparing the joint. With our instructions it works without any problems.