Concreting during frost may be necessary for a variety of reasons. But does it make sense? Because the low temperatures are associated with some risks and disadvantages that must be taken into account.

In a nutshell

- Effort is increased

- Firmness can suffer

- plan longer waiting times

- protective measures required

- special recipes for the winter make sense

Table of contents

- Concreting in frost?

- Preparation

- temperatures

- winter recipes

- deploy

- post-treatment

- frequently asked Questions

Concreting in frost?

Concrete work at low temperatures can make sense because delays have already occurred or are to be prevented. Sometimes there is more free time in winter to do this kind of work. Nevertheless, it is important to be aware of the possible disadvantages and dangers. These are:

- impaired strength

- formation of cracks

- frost damage

- structural damage

- lower density

- reduced bond strength

- delayed strength development

- delayed solidification

- less permanent

In order for these problems not to occur, significantly more effort and longer follow-up treatment must be carried out. This includes, for example, comprehensive protection

of the fresh concrete and a targeted delay in drying out.If concreting cannot be avoided in frost, you should proceed as follows.

Preparation

When concreting in winter, various factors must be considered and prepared. This includes:

- Keep work surfaces, tools and scaffolding free of snow and ice

- Plan for heating options

- have insulating materials ready

- Air, soil and concrete temperature control

- ensure fast processing

In order to avoid drying out too quickly and preventing premature freezing, the concrete must be covered and protected after it has been poured. The necessary setup and covering materials must be readily available. Even if it is foreseeable that the air will need to be heated, a suitable device should already be available.

temperatures

With air and ground temperatures of at least +5 °C, special precautions are only necessary if temperature drops and frost are to be expected. So this is the minimum limit.

In the range from -3 to +5 °C, the fresh concrete must have a temperature of at least 5 °C when it is poured. With LH cements or Mixtures with a cement content less than 240 kilograms per cubic meter, it must be brought to a temperature of 10 °C.

This generally applies to any concrete when temperatures are below -3 °C.

Tip: The 10 °C should be maintained for at least three days after application and then gradually reduced to 5 °C. This gives the concrete enough time to dry and harden evenly.

winter recipes

In the context of concrete, so-called winter recipes are designed to develop a higher heat of hydration and to cure faster. If concreting at low temperatures cannot be avoided, they should be used. They reduce the risk of damage and make follow-up treatment easier.

deploy

After the completed preparation and control of the temperatures, the concrete should be poured quickly. Depending on the size of the area and the required quantity, it is advisable to do this with several helpers to work and on the other hand only mix as much concrete as can be applied within 15 minutes can. Otherwise the temperature of the building material will drop too quickly and problems will arise.

post-treatment

Cold air is dry and therefore has a stronger drying effect on the concrete more quickly. This can cause cracks in the surface.

The concrete must therefore be covered to reduce evaporation. Thermofoil is suitable for this, for example. At the same time, this counteracts rapid cooling. The foil must not lie directly on the surface of the fresh concrete. A distance of a few centimeters between the concrete and the cover is important, in which the moist air can remain. The edges must be sealed as airtight as possible.

Spraying the concrete with water is not recommended in frosty weather. However, it may be necessary to heat the air cushion. A temperature of +10 °C should be maintained at least for the first few days after application.

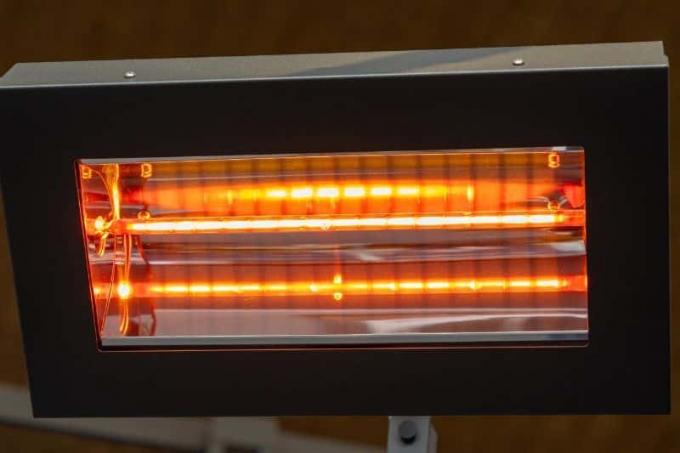

A notice: If the insulation used is not sufficient for this, infrared radiators and other heating options must be used used to provide controlled drying and curing and no frost chipping take risk.

frequently asked Questions

Processing is particularly easy at air temperatures of 5 to 30 degrees Celsius. The optimum is generally 20 degrees Celsius and a high humidity of around 80 percent. The effort for the after-treatment is also significantly lower.

At a temperature of around -10 °C, the drying and hardening of concrete comes to a complete standstill. Even at +5 °C it takes considerably longer and is more difficult. It is therefore better to wait for milder temperatures if at all possible.

No, ice, snow or frozen ground is not suitable for concreting. The properties of the building material are negatively influenced and damage occurs that can only be repaired with great effort.